The next and very important area to have clean is the milking equipment. Milking equipment needs a complete wash at least twice a day. There are five steps to follow when washing the milking equipment.

1. Pre-rinse

Rinse all equipment and utensils and flush the pipeline with lukewarm (100°-110°F) water immediately after use. Dissemble all parts that must be hand washed.

2. Wash

Mix chlorinated alkaline cleaning solution as determined by manufacturer’s recommendations and water quality tests.

-

-

- Gallons of hot water (160°-170°F)

- Ounces of alkaline cleaner

-

For handwashing, you should soak all parts at 120°-135°F for at least 5 minutes. Then, brush all the parts thoroughly and then drain. For pipelines and bulk tanks, you should circulate the cleaning solution for 6-10min. the wash solution temperatures should be above 120°F at the end of the cycle. Run air through for 2-3min and then brush all parts not designed for cleaning by circulating solution including the outside of the tank and outlet drive. Drain all water.

3. Rinse

Rinse the detergent solution with tap water before adding the acid rinse. Rinse the tank thoroughly (inside and out). Rinse tank outlet valve.

4. Acid-Rinse

Rinse pipeline and bulk tank with lukewarm or cold acidified water.

-

-

- Gallons of clean water

- Ounce’s acid cleaner

-

Do not recirculate rinse solution. Circulate for 2-3 minutes and drain. Repeat running air through for 2-3 minutes. Visually inspect the line, receive jar, etc., for proper cleaning.

The last step should be done immediately after milking.

Flush pipelines and bulk tank with sanitizer immediately before milking, using:

-

-

- Gallons of clean water

- Ounces of sanitizer

-

Circulate for 2-3minutes and drain. Sanitize hand-washed parts. Let drain.

Besides the cattle and milk equipment, other things on the farm need to be monitored. Always keep and eye on the waterers as they should be kept clean. Another way to stay clean would be to improving milking technique to stop the spread of bacteria. Always keep an eye on what goes into the feed as well as the feed could be dirty, moldy, and full of bad bacteria. Storing the feed properly and making sure the feed bunk is always clean before putting feed in them will help keep up with the feed hygiene.

Milking Technique to help with cleanliness.

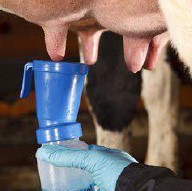

First clean teats with disinfectant solution then thoroughly wipe and dry with a single service towel. Then the milking unit can be put on and you can start milking. After milking is completed, dip each tip fully in a disinfectant solution. Discard any unused solution, clean the container thoroughly and prepare fresh solution at each milking. Great management and keeping things clean will prevent diseases and illness in your herd.

Product of the Week: “O” 1:2 Mineral

“O” 1:2 Mineral is a complete mineral vitamin package specifically designed to meet nutritional needs in dairy cows. “O” 1:2 Mineral is an excellent complement to dairy rations with large amounts of quality alfalfa forage. It also can help solve phosphorus deficiency problems and help prevent tie-up from excess iron.

Product Characteristics:

- Provides calcium and phosphorus (1:2 ratio), including highly available phosphorus from monosodium phosphate and mono/dicalcium phosphate.

- Contains sulfate forms of trace

- Meets daily vitamin needs, including vitamins A, D3 and E.